SCUDO® Radiant

Naturally radiant.

Applications

- Floor radiant heating and cooling systems

- Wall radiant heating and cooling systems

Advantages of the product

High thermal conductivity, to meet the specific needs of low-temperature systems, requiring a smaller inter-tube space.

Extremely low internal roughness, associated with a greater water flow, allows the use of tubes with a limited outer diameter. This allows for reduced flooring slab screed thickness.

Does not suffer the memory effect and therefore does not require thermal insulation panels with positioning “mushrooms” which moreover reduce heat exchange and require greater screed thickness.

It inhibits bacterial growth thus preventing the formation of algae and biofilm inside the tube.

CE Marking

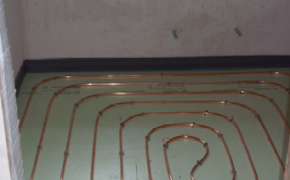

Copper has no memory and this makes this system easy to be installed

Wide pitch thanks to the excellent thermal performance of the copper tube

Completed installation

Main features

SCUDO®Radiant is the ideal solution designed by SCT to meet the specific needs of low-temperature systems. The need to adapt modern systems to alternative energy sources such as heat pumps, solar panels, fireplace stoves or in combination with condensing boilers, in order to achieve maximum energy saving performance, involves the use of installation solutions compatible with these specific systems.

SCUDO®Radiant tube has been designed for compliance to EN 1057 and is intended for underfloor and wall systems. The advanced technical and mechanical characteristics, in particular the high thermal conductivity, constitute the key features that render this product specific for this field of application.

SCUDO®Radiant has a thermal conductivity of 390 W/(mK), that is over 1000 times higher than comparable plastic materials. This fundamental characteristic qualifies it as the primary material in the radiant heating sector; in fact, optimal heat radiation efficiency is achieved by using the material with the best thermal conductivity.

For a given amount of energy consumed to heat a living space, a lower quantity of tubing is required. For this reason, in underfloor systems employing SCUDO®Radiant copper tube the inter-tube space is kept around 25 cm, much wider than that typically used in plastic systems. In addition, its low internal roughness, associated with a greater water flow, allows the use of tubes with a limited outer diameter. This allows for reduced flooring slab screed thickness with a consequent lower occupation of the building structure and obvious savings in construction costs. These advantages ultimately sustain lower pressure drops and lower energy consumption for the circulation pumps, in addition to energy saving in the boiler, since the water can circulate at low temperature, and in turn, this causes reduced wear of the system components.

Another important advantage in terms of increased savings and living comfort is obtained thanks to lower thermal inertia: the desired ambient temperature is reached more quickly.

Technical characteristics

•Resistance to heat and fire: melting point 1083 °c; SCUDO®Radiant

Can easily sustain rapid temperature fluctuations, without the risk of softening in the event of boiling water or other deformation phenomena that would shorten useful life.

• High burst pressure.

• Long life: absence of deterioration and cracks from fatigue due to temperature variations and ageing (the problem particularly acute for heating/cooling systems with heat pumps).

• Low and unique thermal expansion coefficient similar to that of the screed.

• It inhibits bacterial growth thus preventing the formation of algae and biofilm inside the tube.

• Absolute impermeability to gases and UV resistance: no problems of osmosis and negative consequences on plant components (boiler, pump impellers and other metal parts).

The particular manufacturing process adopted for SCUDO®Radiant allows for a malleable and easily installable product, which does not suffer the memory effect and therefore does not require thermal insulation panels with positioning “mushrooms” which moreover reduce heat exchange and require greater screed thickness. It is compatible with the normal plasters and mortars normally available in the market and does not require additives to increase fluidisation and thermal conductivity.

SCUDO®Radiant copper tube is perfectly aligned to modern Bio-architecture principles that focus onhealth and ambient comfort issues by calling attention to the choice of materials and related environmental sustainability. This material is completely natural, non-toxic, non-magnetic and 100% recyclable. At the end of its extended life cycle it retains a very high recovery value, as opposed to other materials that involve considerable disposal costs.

Furthermore, in the interests of consumer protection and in accordance with EU Regulation 305/2011 for construction products (CPR), SCUDO® copper tubes are certified with the CE mark. A further guarantee of compliance with prevailing regulation standards is assured with the achievement of UNI-IGQ Quality certification.

Scope of supply

Seamless, drawn copper tube, produced in accordance with EN 1057, R220 annealed physical status, phosphorised Cu DHP (Cu + Ag : 99.90% min. – P: 0.015÷0.040%) according to EN 1412, treatment of pre-passivation on the internal surface of the tube with a carbon residue of less than 0.06 mg/dm2, indelible labelling every 60 cm with punching of the external surface of the copper tube, CE labelled in compliance with EU Regulation 305/2011 for construction products (CPR) specific for the production of underfloor heating panel systems in accordance with standard EN 1264, dimensions 14 x 0.8mm.